Introduction: The Essential Geosynthetic for Foundational Stability

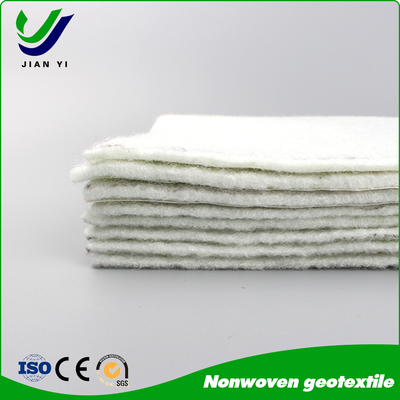

Discover the fundamental role of staple fiber non-woven geotextiles in modern construction and civil engineering. Engineered from synthetic fibers through a meticulous needle-punching process, our geotextiles create a durable, permeable fabric that is indispensable for separation, filtration, drainage, and protection. As a cost-effective and highly efficient solution, they are the first choice for a multitude of applications, from roadways and drainage systems to erosion control and landscaping.

Key Features & Benefits

1. Superior Separation

Our staple fiber geotextiles prevent the intermixing of distinct soil layers, such as aggregate and subsoil. By maintaining the integrity and structural capacity of each layer, they extend the service life of paved and unpaved roads, rail beds, and other foundational structures, reducing long-term maintenance costs.

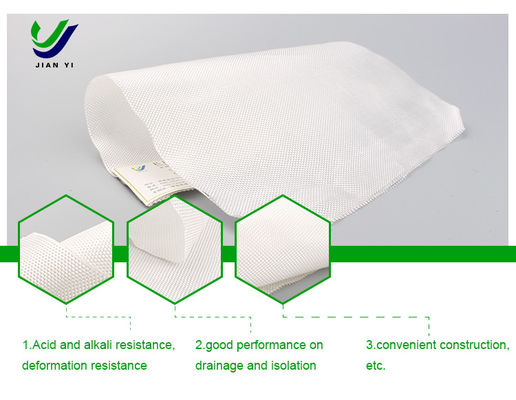

2. Excellent Filtration

Acting as a filter, our geotextiles allow for the controlled passage of water while preventing the migration of fine soil particles. This crucial function protects drainage systems from clogging and ensures their long-term performance in applications like French drains, retaining walls, and shoreline protection.

3. Enhanced Drainage

The non-woven, felt-like structure provides in-plane permeability, facilitating the lateral flow of water and gases. This helps to dissipate pore water pressure and accelerate consolidation in soils, making them ideal for use behind retaining walls and in landfill leachate collection systems.

4. Reliable Protection

Our geotextiles act as a cushioned, protective layer for delicate geomembranes and other liners. They shield them from puncture and damage caused by sharp aggregates or irregular subgrades, ensuring the long-term integrity of critical containment barriers in ponds, landfills, and lagoons.

5. High Permeability & Porosity

With a high flow rate and open structure, water passes through easily without compromising the fabric's filtering efficiency. This balance is key to preventing hydrostatic pressure buildup and ensuring system stability.

6. Durability and Puncture Resistance

The needle-punched structure creates a strong, entangled web of fibers that offers high tensile strength and exceptional resistance to punctures and tears during installation and throughout its service life.

7. UV and Chemical Resistance

Treated for enhanced UV stability, our geotextiles can withstand prolonged exposure to sunlight during installation. They also offer good resistance to soil chemicals, mildew, and rotting, ensuring consistent performance in harsh environments.

Primary Applications

-

Road and Railway Construction: Separation and stabilization between subgrade and aggregate base layers.

-

Drainage Systems: Filtration layer in French drains, trench drains, and around perforated pipes.

-

Landfill and Environmental Protection: Protection layer for geomembrane liners, filtration in leachate collection systems.

-

Erosion Control: Underlayer for riprap in shoreline and riverbank revetments.

-

Landscaping and Agriculture: Weed barrier, separation layer under sidewalks and patios, soil stabilization for turf.

-

Retaining Walls: Drainage and filtration layer behind retaining structures.

Material & Physical Properties

-

Material: 100% Virgin Polypropylene or Polyester

-

Structure: Non-Woven, Needle-Punched

-

Available Weights: Ranging from 3 oz/yd² to 16 oz/yd² (100 g/m² to 500 g/m²) to suit specific project strength and permeability requirements.

-

Roll Dimensions: Standard widths of 4.5m or 5.0m (15ft or 16.5ft) and lengths of 100m or 330ft (100 yards) for efficient installation and minimal seams.

All our staple fiber geotextiles are manufactured to meet relevant international standards, including ASTM and GRI specifications, ensuring consistent quality and performance.

Installation Guidance

For optimal performance, proper installation is key:

-

Subgrade Preparation: The subgrade should be smooth, compacted, and free of sharp debris.

-

Placement: Rolls are placed manually or mechanically and unrolled smoothly across the prepared area.

-

Overlap: Adjacent rolls should have a minimum side and end overlap of 12-18 inches (300-450mm). On slopes, overlap should be oriented downhill.

-

Backfilling: Backfill should be placed carefully from the center outwards to avoid displacing the geotextile. Avoid dropping aggregate from excessive heights.

Why Choose Our Staple Fiber Geotextile?

-

Consistent Quality: Manufactured under strict quality control for uniform weight, thickness, and strength.

-

Technical Support: Our experts can help you select the right weight and specification for your project's unique soil and load conditions.

-

Proven Performance: Trusted by contractors and engineers for foundational support in a wide range of civil and environmental projects.

-

Cost-Effective: An economical solution that significantly enhances project longevity and reduces material consumption.

Request a Quote or Technical Support

Selecting the correct geotextile is critical for project success. Contact us today for a free consultation, detailed technical data sheets, and samples to test for your specific application.

Build a Stronger Foundation. Ensure Long-Term Performance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!