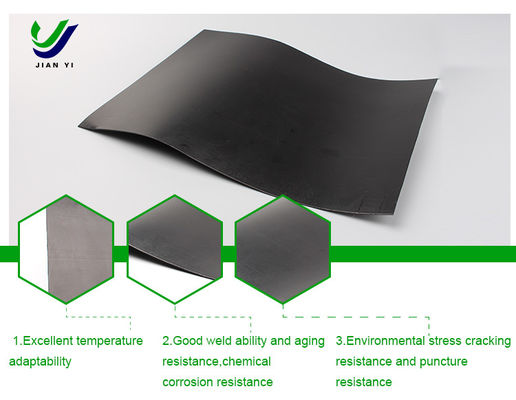

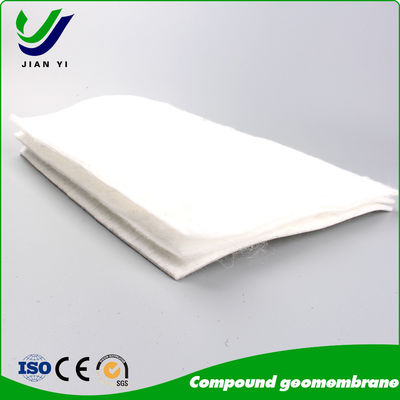

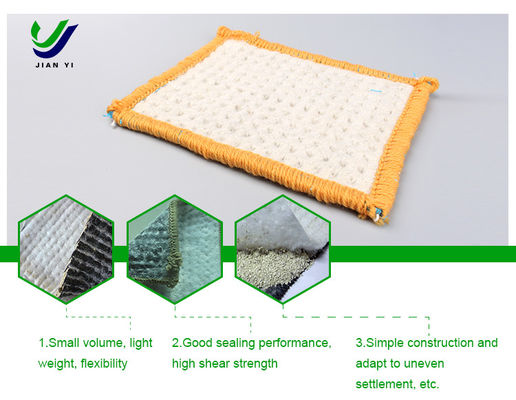

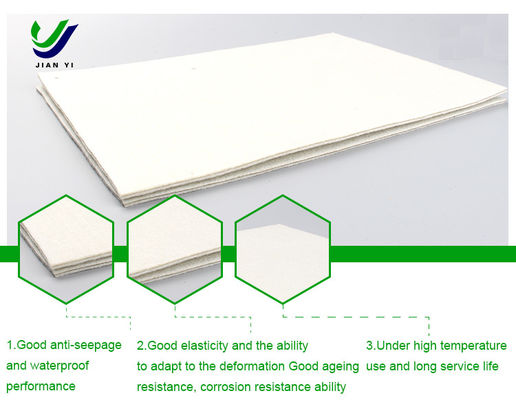

Our Composite Geomembrane is a high-performance engineered material that combines the strength of geotextiles with the impermeability of polymer membranes. Designed for critical containment applications, it provides superior leak prevention, durability, and structural reinforcement in environmental, hydraulic, and civil engineering projects.

Key Features & Benefits

✔ Superior Waterproofing

– Multi-layer design with a high-density polyethylene (HDPE), polyvinyl chloride (PVC), or linear low-density polyethylene (LLDPE) membrane core ensures zero liquid penetration.

– Ideal for landfills, reservoirs, and wastewater treatment to prevent contamination.

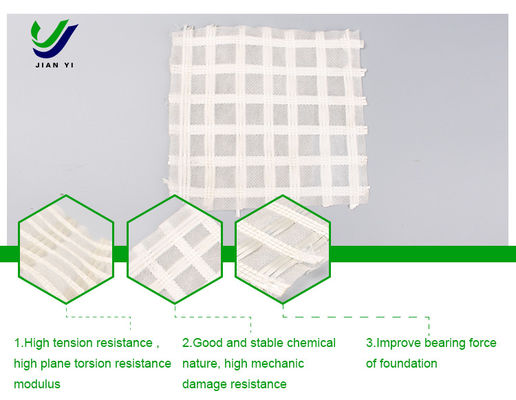

✔ Enhanced Strength & Durability

– Reinforced with woven/nonwoven geotextile layers for high tensile strength and puncture resistance.

– UV-stabilized and chemical-resistant for long-term outdoor exposure.

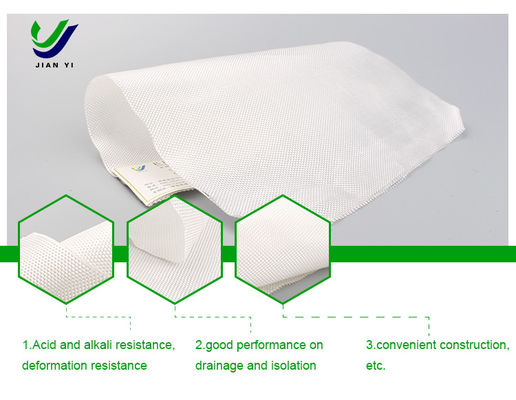

✔ Flexible & Easy to Install

– Lightweight and foldable, allowing for quick deployment on slopes, curves, and uneven terrain.

– Can be thermally welded or seamed for seamless, leak-proof joints.

✔ Cost-Effective & Sustainable

– Reduces the need for multiple material layers, saving time and labor costs.

– Environmentally safe, non-toxic, and recyclable.

Applications

• Landfill Liners & Caps – Prevents leachate and gas migration.

• Water & Wastewater Containment – Used in ponds, canals, and treatment plants.

• Mining & Oilfield Projects – Secures tailings and prevents seepage.

• Agricultural & Aquaculture Ponds – Maintains water retention.

• Tunnel & Underground Waterproofing – Protects against moisture infiltration.

Technical Specifications

| Application |

Landfill/ Reservoir/ Lagoon/ Canal/ Construction Site |

| Elongation at Break |

≥600% |

| Installation Method |

Hot Wedge Welding/Extrusion Welding |

| Chemical Resistance |

Excellent |

| Material |

HDPE/LDPE/LLDPE |

| Temperature Resistance |

-70℃ To 80℃ |

| Puncture Resistance |

≥120N |

| Color |

Black/White/Green/Blue |

| Weight |

200-1500g/㎡ |

| Thickness |

0.2mm-3.0mm |

Customization Options

• Material Choice – HDPE (high chemical resistance), PVC (flexibility), or LLDPE (stress crack resistance).

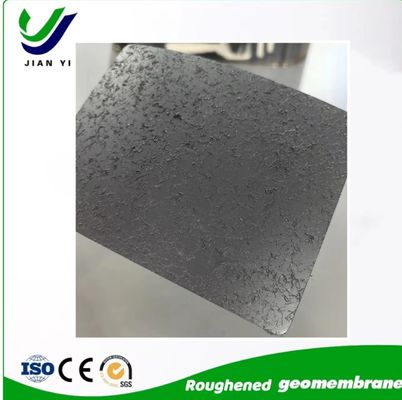

• Surface Texture – Smooth, textured (for friction enhancement), or coated (for extra protection).

• Reinforcement – Nonwoven (filtration) or woven (high strength) geotextile backing.

Why Choose Our Composite Geomembrane?

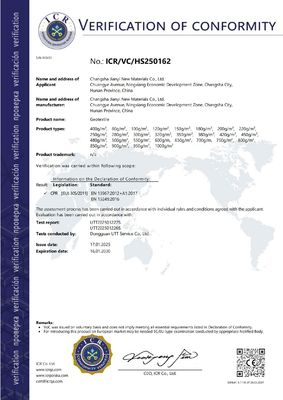

Certified Quality – Complies with CE and ISO standards.

Expert Support – Technical guidance from selection to installation.

Global Supply – Reliable logistics and bulk order discounts.

Request a Quote Today!

Upgrade your project with a leak-proof, durable, and cost-efficient geomembrane solution. Contact us now for specifications and pricing!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!