0.2mm-3.0mm Thickness HDPE/LDPE/LLDPE Isolation Film with Protection

Product Description:

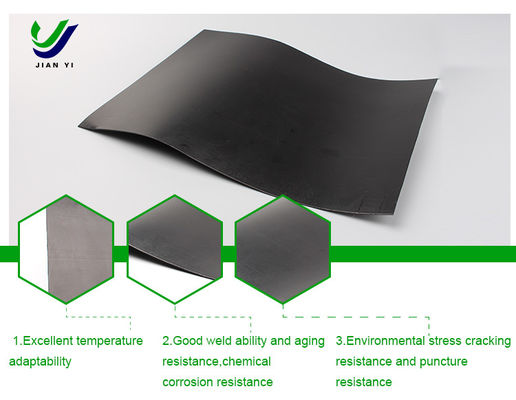

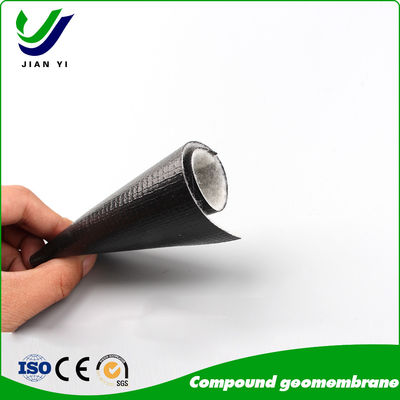

The Compound Geomembrane is a versatile and durable product designed to meet the needs of various applications such as landfill, reservoir, lagoon, canal, and construction sites. With its exceptional puncture resistance of ≥120N, this geomembrane provides reliable protection against punctures and tears, ensuring long-lasting performance in demanding environments.

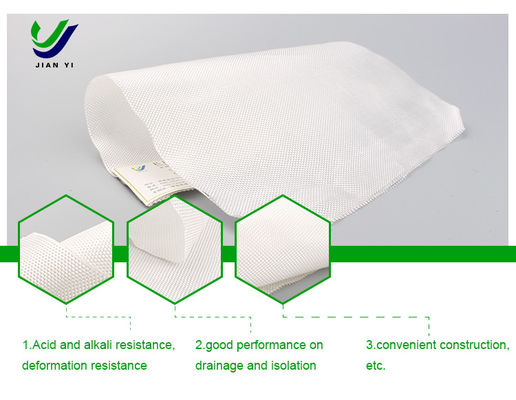

Available in a range of thicknesses from 0.2mm to 3.0mm, the Compound Geomembrane offers flexibility and strength to suit different project requirements. Whether you need a thinner membrane for lighter applications or a thicker one for added protection, this product delivers consistent quality and performance.

Choose from a selection of colors including black, white, green, and blue to meet your aesthetic preferences or project specifications. The variety of colors available allows for customization and integration with the surrounding environment, providing both functionality and visual appeal.

With widths ranging from 1m to 8m, the Compound Geomembrane offers versatility in installation and coverage options. Whether you need a narrow strip to line a canal or a wide sheet to cover a large reservoir, this geomembrane can be tailored to fit your project dimensions with ease.

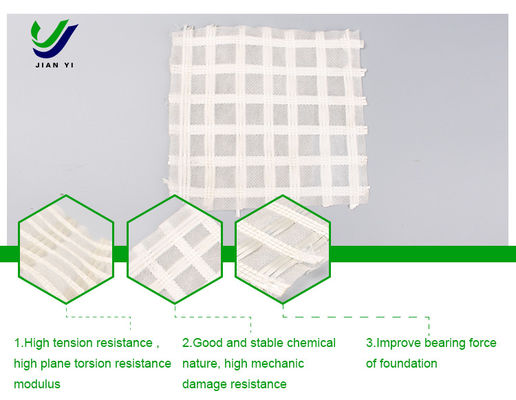

Its reinforced design enhances its durability and resistance to wear and tear, making it ideal for long-term applications that require reliable performance. The added reinforcement provides strength and stability, ensuring the geomembrane maintains its integrity under various conditions.

Whether used in a landfill to prevent leakage, in a reservoir to contain water, in a lagoon to protect the environment, in a canal to control water flow, or at a construction site to provide a barrier, the Compound Geomembrane excels in its versatility and reliability. Its puncture resistance, range of thicknesses, color options, widths, and reinforced structure make it a trusted choice for a wide range of applications.

Features:

- Product Name: Compound Geomembrane

- Puncture Resistance: ≥120N

- Thickness: 0.2mm-3.0mm

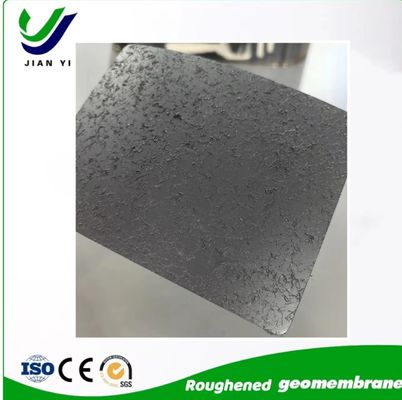

- Surface: Smooth/Textured

- Tensile Strength: ≥20MPa

- Tear Resistance: ≥80N

Technical Parameters:

| Technical Parameter |

Value |

| UV Resistance |

≥70% |

| Color |

Black/White/Green/Blue |

| Elongation at Break |

≥600% |

| Tensile Strength |

≥20MPa |

| Installation Method |

Hot Wedge Welding/Extrusion Welding |

| Application |

Landfill/Reservoir/Lagoon/Canal/Construction Site |

| Puncture Resistance |

≥120N |

| Material |

HDPE/LDPE/LLDPE |

| Chemical Resistance |

Excellent |

| Weight |

200-1500g/㎡ |

Applications:

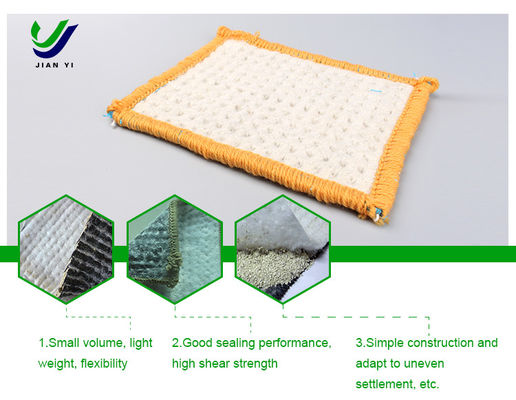

Road and Railway Construction: Composite geotextiles are used to reinforce soil, improve stability, and enhance the load-bearing capacity of roadbeds and railway tracks. They help in distributing loads evenly and reducing the risk of settlement.

Drainage Systems: These materials are employed in drainage systems to facilitate the efficient removal of water, preventing waterlogging and maintaining the structural integrity of the construction. They are often used in conjunction with drainage pipes and aggregates.

Landfill Liners and Caps: In landfill engineering, composite geotextiles are used as part of the liner and capping systems to prevent leachate from contaminating the surrounding soil and groundwater. They provide a barrier to harmful substances while allowing for gas venting.

Erosion Control: They are used in slope stabilization and erosion control projects to protect soil from being washed away by water or wind. This is particularly important in areas prone to heavy rainfall or on steep slopes.

Retaining Walls and Embankments: Composite geotextiles are used to reinforce retaining walls and embankments, providing additional strength and stability. They help in reducing the lateral pressure exerted by the soil.

Hydraulic Engineering: In applications such as dams, canals, and coastal protection, composite geotextiles are used to enhance the durability and performance of these structures. They help in controlling water flow and protecting against erosion.

Agriculture: They are used in agricultural applications for soil stabilization, moisture retention, and weed control. This helps in improving crop yield and maintaining soil health.

Tunnels and Underground Structures: In tunnel construction, composite geotextiles are used for waterproofing, drainage, and reinforcement. They help in maintaining the structural integrity of tunnels and preventing water ingress.

Recreational Areas: They are used in the construction of sports fields, golf courses, and other recreational areas to improve drainage, stabilize the soil, and provide a stable surface for activities.

Environmental Protection: Composite geotextiles are used in various environmental protection projects, such as the construction of wetlands, riverbank protection, and habitat restoration. They help in maintaining ecological balance and protecting natural habitats.

Overall, composite geotextiles play a crucial role in modern engineering and environmental projects by providing solutions for reinforcement, filtration, drainage, and protection.

Customization:

Product Customization Services for Compound Geomembrane:

Chemical Resistance: Excellent

Material: HDPE/LDPE/LLDPE

Color: Black/White/Green/Blue

UV Resistance: ≥70%

Elongation at Break: ≥600%

Support and Services:

Our Product Technical Support and Services for the Compound Geomembrane include:

- Installation guidance and recommendations

- Maintenance and repair assistance

- Performance monitoring and evaluation

- Customized solutions for specific project requirements

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!