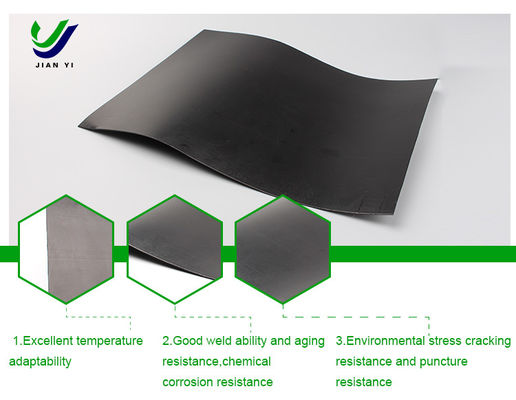

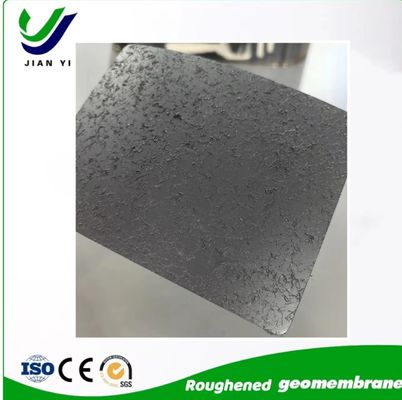

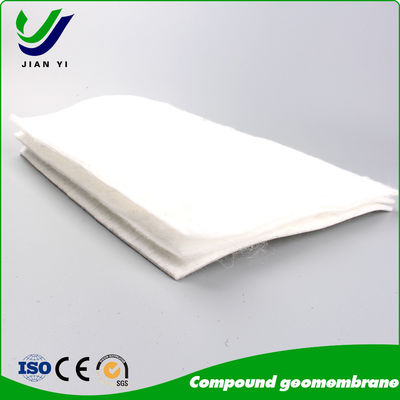

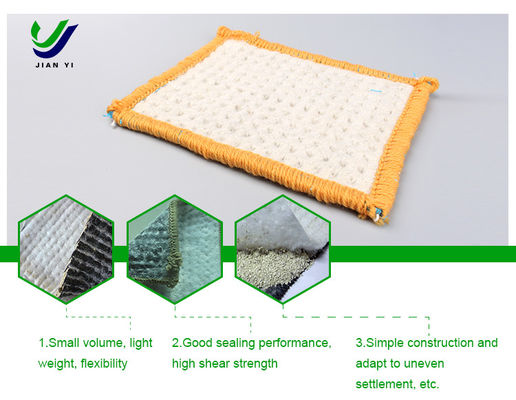

The Composite Geomembrane is a high-performance, multi-layered geosynthetic material designed for superior containment, barrier protection, and environmental safety. Combining the strength of geotextiles with the impermeability of geomembranes, this product offers unmatched durability, flexibility, and resistance to environmental stressors. It is widely used in applications such as landfill liners, pond and reservoir liners, mining operations, and environmental protection projects.

Key Features:

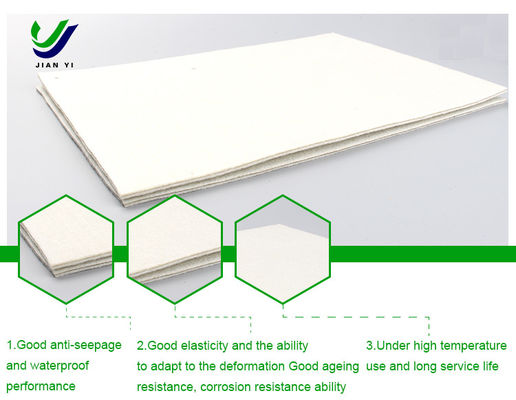

Exceptional Impermeability:

The geomembrane layer provides an impermeable barrier, effectively preventing the leakage of liquids, gases, and contaminants. This makes it ideal for applications requiring strict containment, such as hazardous waste storage and water conservation.

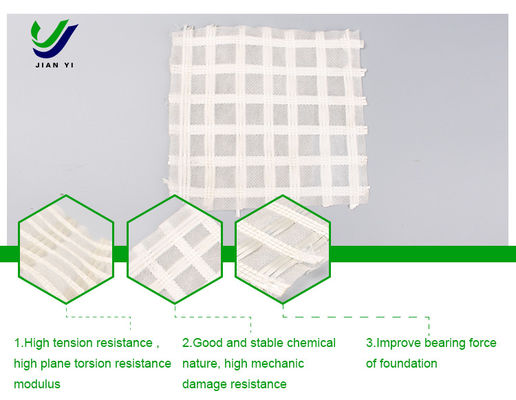

High Tensile Strength:

Reinforced with geotextile layers, the composite geomembrane exhibits excellent tensile strength and puncture resistance, ensuring long-term performance even under heavy loads and harsh conditions.

UV and Chemical Resistance:

Manufactured from high-quality polymers, the geomembrane is resistant to UV radiation, chemical degradation, and biological attack, making it suitable for both exposed and buried applications.

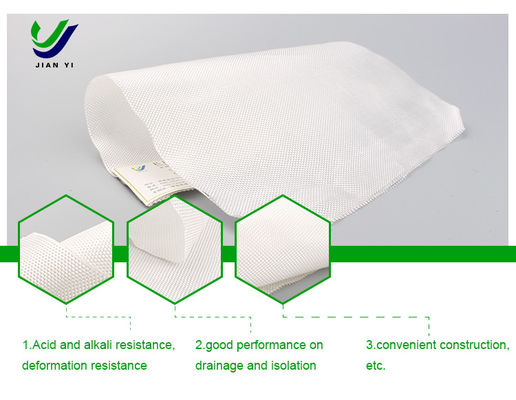

Flexibility and Adaptability:

The composite geomembrane is highly flexible, allowing it to conform to irregular surfaces and accommodate ground movements without compromising its integrity.

Easy Installation:

Lightweight and available in large rolls, the composite geomembrane is easy to transport, handle, and install, reducing labor costs and project timelines.

Environmental Protection:

By preventing the migration of pollutants and conserving water resources, the composite geomembrane contributes to sustainable development and environmental protection.

Applications:

Landfill Liners and Caps: Provides a reliable barrier to prevent leachate contamination of soil and groundwater.

Pond and Reservoir Liners: Ensures water retention and prevents seepage in agricultural, industrial, and recreational water storage systems.

Mining Operations: Used in heap leach pads, tailings dams, and containment ponds to manage process fluids and prevent environmental contamination.

Wastewater Treatment: Lines lagoons and tanks to contain and treat wastewater effectively.

Aquaculture: Creates durable and safe containment systems for fish and shrimp farming.

Environmental Remediation: Isolates contaminated sites to prevent the spread of pollutants.

Specifications:

Material: High-Density Polyethylene (HDPE), Linear Low-Density Polyethylene (LLDPE), or Polyvinyl Chloride (PVC) geomembrane laminated with non-woven geotextile.

Thickness: Available in various thicknesses (e.g., 0.5mm to 3.0mm).

Width: Standard rolls of 2m to 8m wide, customizable to project requirements.

Tensile Strength: High tensile strength to withstand mechanical stress.

Puncture Resistance: Excellent resistance to punctures and tears.

Temperature Range: Performs reliably in a wide temperature range, from -50°C to 80°C.

Product Specification and Technical Index (GB/T 17642-2008)

| Item |

Specifications |

Remark |

| Geotextile Unit Weight (g/㎡) |

300 |

500 |

600 |

700 |

800 |

900 |

1000 |

1100 |

|

| Geomembrane Thickness (mm) |

0.25-0.35 |

0.30-0.50 |

|

| Nominal Fracture Strength (KN/m) |

2.50 |

7.50 |

10 |

12 |

14 |

16 |

18 |

20 |

|

| Breaking Strength (KN/m,≥,LD/TD) |

2.50 |

7.50 |

10 |

12 |

14 |

16 |

18 |

20 |

|

| Standard Intensity Corresponding Elongation Rate (%) |

30~100 |

|

| CBR Burst Strength (KN,≥) |

0.70 |

1.50 |

1.90 |

2.20 |

2.50 |

2.80 |

3.00 |

3.20 |

|

| Longitudinal Tear Strength (KN,≥) |

0.05 |

0.25 |

0.32 |

0.40 |

0.48 |

0.56 |

0.62 |

0.70 |

|

| Hydrostatic Pressve (Mpa) |

See List Below |

|

| Peel Strength (N/cm,≥) |

6 |

|

| Vertical Permeability Coefficient (cm/s) |

According to design or contract mentioned. |

|

| Width Variation (%) |

-1.00 |

|

|

Specification

Item |

Geomembrane Thickness (mm) |

Remark |

| 0.20 |

0.30 |

0.40 |

0.50 |

0.60 |

0.70 |

0.80 |

1.00 |

| Hydrostatic Pressve (Mpa) |

One geotextiles with one geomembrane |

0.40 |

0.50 |

0.60 |

0.80 |

1.00 |

1.20 |

1.40 |

1.60 |

|

| Two geotextiles with one geomembrane |

0.50 |

0.60 |

0.80 |

1.00 |

1.20 |

1.40 |

1.60 |

1.80 |

|

Installation Guidelines:

Surface Preparation:

Ensure the subgrade is smooth, compacted, and free of sharp objects or debris that could damage the geomembrane.

Unrolling and Positioning:

Unroll the composite geomembrane and position it carefully, ensuring proper alignment and minimal wrinkles.

Seaming and Welding:

Overlap adjacent sheets and use thermal fusion welding, extrusion welding, or adhesive bonding to create strong, leak-proof seams.

Anchoring and Protection:

Secure the edges of the geomembrane with anchor trenches or mechanical fasteners. Cover the geomembrane with a protective layer (e.g., soil or geotextile) to prevent UV exposure and mechanical damage.

Why Choose Our Composite Geomembrane?

Our Composite Geomembrane is engineered to meet the highest industry standards, ensuring reliable performance in even the most demanding applications. With a focus on quality, durability, and environmental sustainability, this product is the ideal choice for your containment and protection needs.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!