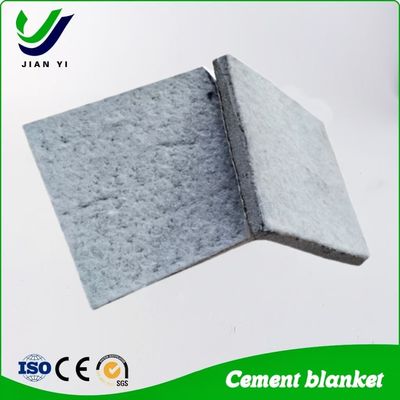

Concrete Canvas, also known as "concrete cloth," is a flexible fabric impregnated with cement that hardens upon hydration, forming a thin, durable, waterproof, and fire-resistant concrete layer. Reinforced with fibers for enhanced toughness and strength, it resists cracking and outperforms traditional concrete in longevity, with a service life of 10–20 years under comparable conditions.

What is Concrete Canvas Used For?

Concrete Canvas has a wide range of applications, including:

Pond & fish tank slope protection

Riverbank & channel reinforcement

Ditch & drainage system upgrades

Erosion control & soil stabilization

Infrastructure reinforcement (roads, bridges, tunnels)

Its ease of installation makes it ideal for preventing soil erosion while providing structural reinforcement.

How to Install Concrete Canvas?

1. Preparation

Plan and measure the slope to ensure proper water flow.

Clear and level the construction area, marking guidelines according to the design.

Recheck the drainage slope before proceeding.

2. Excavation

Dig trenches following the design specifications.

Ensure side slopes are smooth, free of loose soil or voids.

Compact weak areas and remove debris/rocks.

If necessary, reinforce with lime-soil compaction (3:7 ratio) or grouting before sealing.

3. Laying the Concrete Canvas

Can be installed longitudinally or transversely.

The base must be perfectly flat to avoid aesthetic defects.

4. Seam Treatment

4.1 Dig a 10 cm-wide, half-thickness groove at overlapping sections and press the joint flat.

4.2 Overlap sheets ≥10 cm along the water flow direction.

4.3 Apply sealant evenly over the seam.

4.4 Secure both layers with Ø5×38 mm stainless steel screws.

5. Edge Fixing

Anchor the edges to the trench using rivets.

Cover the fixed edges with soil for a seamless finish.

6. Water Activation & Curing

Inspect before watering!

Water requirement: 9 kg/m² (for 10 mm thickness) – ensure full saturation.

Watering method:

Spray evenly from edges to center (avoid high-pressure jets).

Optimal flow rate: 400 ml/min until the fabric darkens.

Post-watering precautions:

No foot traffic during curing.

Below 5°C? Use insulation.

Above 30°C? Cover with plastic/geotextile to retain moisture.

Curing time: ≥3 days of moist curing.

Key Advantages Over Traditional Concrete

✔ Faster installation – No mixing, pouring, or formwork needed.

✔ Higher flexibility – Conforms to complex shapes without cracking.

✔ Superior durability – Resists water, chemicals, and UV degradation.

✔ Eco-friendly – Reduces material use by up to 95% vs. conventional concrete.

Ideal for rapid deployment in erosion control, slope stabilization, and waterproofing projects!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!