0.2~3mm Thickness Compound Geomembrane For Landfill Mining

Product Introduction

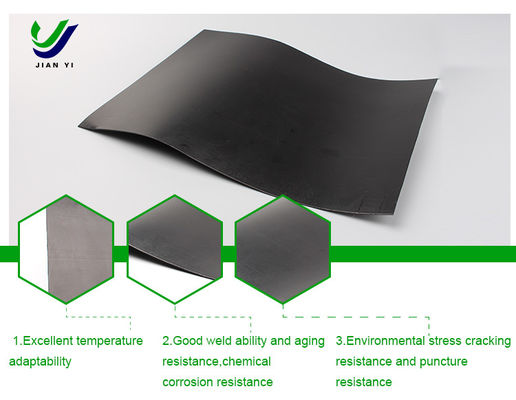

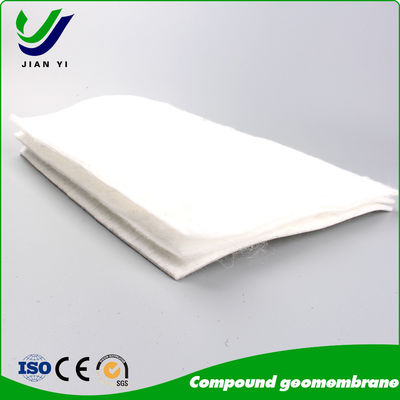

Composite Geomembrane is a high-performance engineered material combining a durable HDPE geomembrane with a nonwoven geotextile fabric. This dual-layer design offers exceptional hydraulic barrier properties, enhanced puncture resistance, and superior drainage capabilities, making it ideal for projects requiring both containment and filtration. Widely used in environmental, civil, and hydraulic engineering, it ensures long-term reliability in harsh conditions.

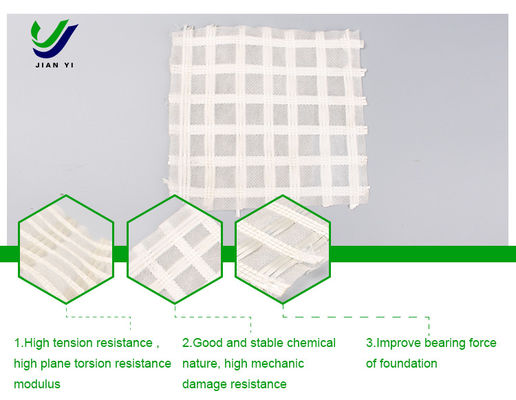

Advantages of Composite geomembrane

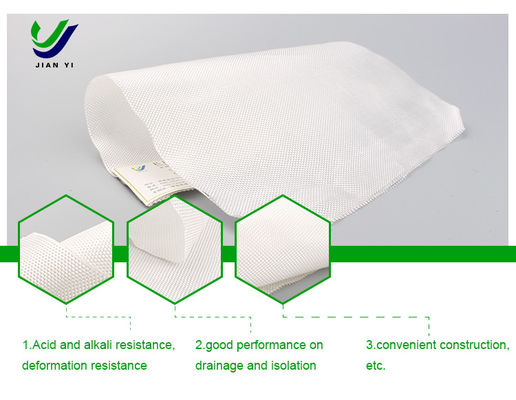

Dual-Layer Protection

HDPE Layer: Provides impermeability, UV resistance, and chemical stability.

Geotextile Layer: Adds puncture resistance, distributes stress, and facilitates drainage.

High Tensile Strength

Withstands heavy loads and ground settlement without tearing (≥30 kN/m tensile strength).

Easy Installation

Pre-bonded layers eliminate the need for separate geotextile deployment.

Cost Efficiency

Reduces labor and material costs by combining two functions in one product.

Environmental Compliance

NSF/ANSI 61 certified for potable water applications and landfill lining.

Composite Geomembrane Production Process

Material Selection

Virgin HDPE resin + high-strength polyester/polypropylene geotextile.

Lamination

Heat-bonding or needle-punching technology to fuse HDPE and geotextile.

Quality Control

Thickness uniformity checks, peel strength tests (≥6 N/cm), and seam integrity verification.

Rolling & Packaging

Custom widths (2m–10m) and lengths (50m–200m), protected with anti-UV wrapping.

Our product parts of testing equipments:

Thickness Tester Fiber Strength Tester Carbon Black Tester

Product Application

Landfills: Base liners and caps with integrated drainage.

Water Infrastructure: Canals, reservoirs, and wastewater treatment ponds.

Mining: Tailings storage and heap leach pads.

Transportation: Road embankments and railway subgrade stabilization.

Agriculture: Irrigation ponds and biogas digesters.

Product Specification

Jianyi have Eight production lines, so we can supply complete specifications to meet different requirements of our customers.

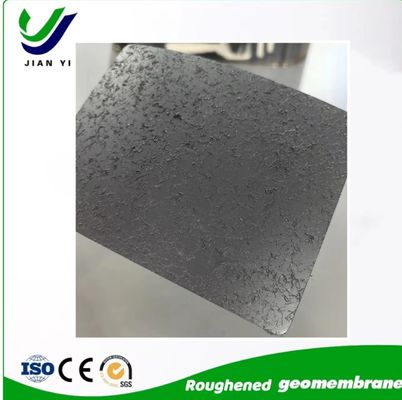

- Smooth geomenbrane and Rough geomenbrane production line.

- Long fiber geotextile production line and Staple fiber geotextile production line

- Composite geomembrane production line

- 3m and 6m Compound drainage network production line

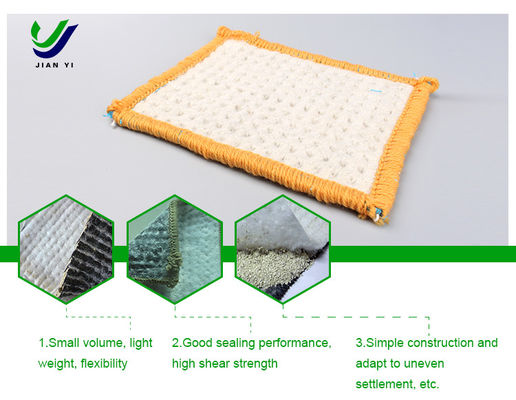

- Bentonite waterproof blanket production line

Product Specifications of Jianyi as follows:

* Thickness(mm): 0.30mm~3.00mm

* Width:1m~9m

* Roll length: 30m~100m (customized request accept)

PS: Customized request accept for all above.

Product Specification and Technical Index (GB/T 17642-2008)

| Item |

Specifications |

Remark |

| Geotextile Unit Weight (g/㎡) |

300 |

500 |

600 |

700 |

800 |

900 |

1000 |

1100 |

|

| Geomembrane Thickness (mm) |

0.25-0.35 |

0.30-0.50 |

|

| Nominal Fracture Strength (KN/m) |

2.50 |

7.50 |

10 |

12 |

14 |

16 |

18 |

20 |

|

| Breaking Strength (KN/m,≥,LD/TD) |

2.50 |

7.50 |

10 |

12 |

14 |

16 |

18 |

20 |

|

| Standard Intensity Corresponding Elongation Rate (%) |

30~100 |

|

| CBR Burst Strength (KN,≥) |

0.70 |

1.50 |

1.90 |

2.20 |

2.50 |

2.80 |

3.00 |

3.20 |

|

| Longitudinal Tear Strength (KN,≥) |

0.05 |

0.25 |

0.32 |

0.40 |

0.48 |

0.56 |

0.62 |

0.70 |

|

| Hydrostatic Pressve (Mpa) |

See List Below |

|

| Peel Strength (N/cm,≥) |

6 |

|

| Vertical Permeability Coefficient (cm/s) |

According to design or contract mentioned. |

|

| Width Variation (%) |

-1.00 |

|

| |

Specification

Item |

Geomembrane Thickness (mm) |

Remark |

| 0.20 |

0.30 |

0.40 |

0.50 |

0.60 |

0.70 |

0.80 |

1.00 |

| Hydrostatic Pressve (Mpa) |

One geotextiles with one geomembrane |

0.40 |

0.50 |

0.60 |

0.80 |

1.00 |

1.20 |

1.40 |

1.60 |

|

| Two geotextiles with one geomembrane |

0.50 |

0.60 |

0.80 |

1.00 |

1.20 |

1.40 |

1.60 |

1.80 |

|

Jianyi ---Your Professional HDPE Geomembrane Sheet Manufacturer

Jianyi New Material Co.,Ltd, which is the professional manufacturer specialized in R&D, produce, sales and installation of environmentally friendly materials.

We have one advanced imported geomembrane production line, two world-class HDPE geomembrane production lines, and one textured HDPE geomembrane production line. Our capacity of HDPE geomembrane can be 60 metric tons per day.

Jianyi is the largest manufacturer of HDPE geomembrane in Hunan,we are one of the member units of HNWPA.

We have certificated by ISO9001, ISO14001 ISO45001 and CE.

ISO9001:2015 ISO14001:2015 ISO45001:2018 CE:2025

We have about 20 patents, part of them as follows:

Patent for Geotextile Netting Machine/Composite geomat patent/Patent for composite film trimming device ect.

Changsha Jianyi have participated in many large-scale exhibitions abroad, such as Indonsia, Vietam, Russia , India, Philippine, Myanmar, Combodia etc ,our HDPE geomembrane products are deeply loved by exhibitors.

Changsha Jianyi have built a long term cooperation with many famous enterprises:

Composite Geomembrane Installation Specification

Subgrade Preparation

Remove debris, compact soil, and ensure a smooth surface.

Unrolling

Align rolls parallel to slopes; overlap edges by 10–15cm.

Seaming

HDPE Layer: Use hot wedge welding (dual-track recommended).

Geotextile Layer: Stitch or thermally bond overlaps.

Anchoring

Bury edges in anchor trenches or secure with ballast.

Protection

Cover with soil or sand (min. 30cm layer) to prevent UV degradation.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!