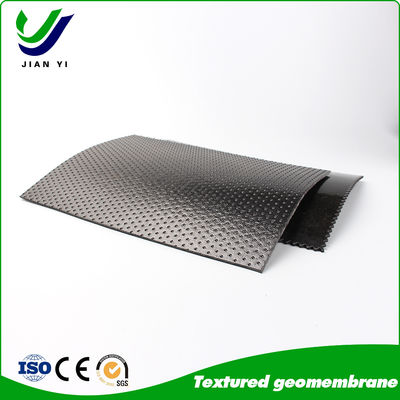

Textured Geomembrane: Superior Friction Resistance for Enhanced Slope Stability and Critical Containment

Introduction: Engineered for Stability in Demanding Applications

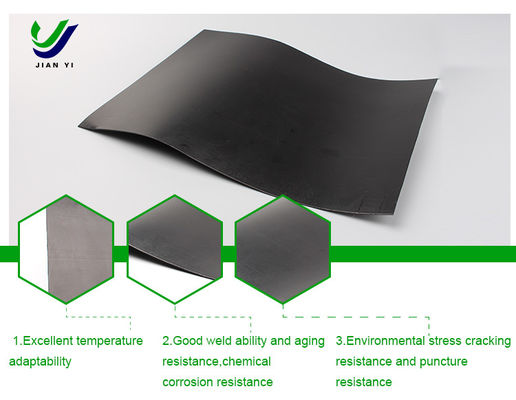

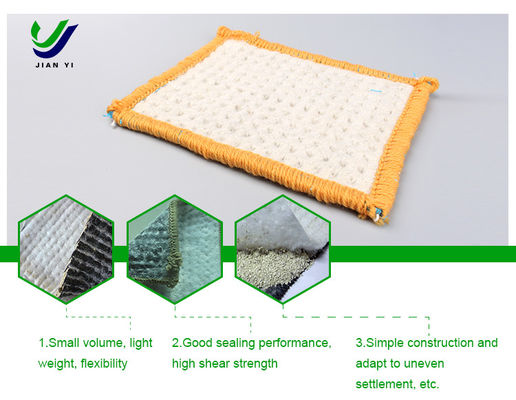

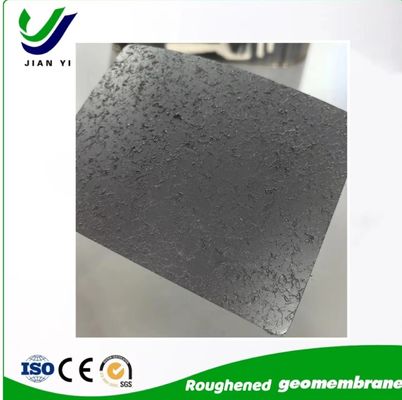

Textured Geomembrane represents a significant advancement in geosynthetic barrier technology. Designed with an intentionally roughened surface, this high-density polyethylene (HDPE) membrane delivers exceptional interface friction coefficients, making it the ideal choice for projects where slope stability is paramount.

Unlike smooth geomembranes, its unique textured surface, achievable through either stud (columnar point) or spray-on roughening processes, provides superior grip with adjacent soils and geosynthetics, ensuring long-term structural integrity in challenging environmental containment applications like landfill liners, reservoir dams, and mining facilities.

What is a Textured Geomembrane?

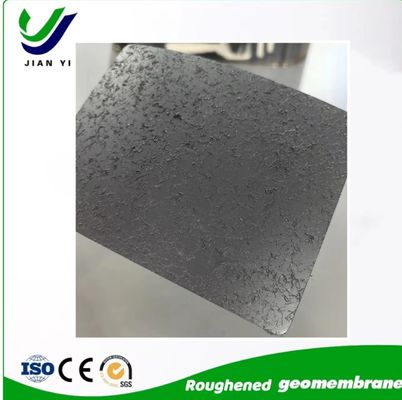

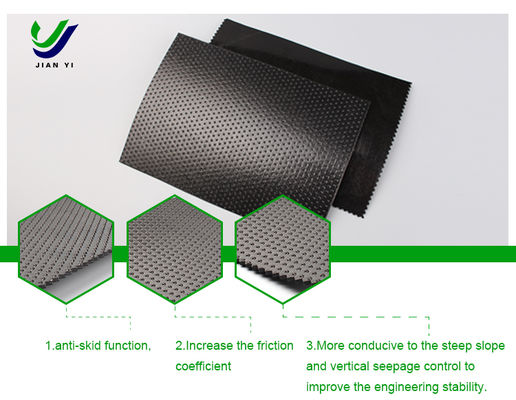

A Textured Geomembrane is a flexible impermeable liner manufactured from premium-grade HDPE resin. Its key differentiator is a single-sided or double-sided roughened surface texture. This texture is specifically engineered to increase the surface's friction characteristics.

The primary production methods include:

- Stud/Columnar Point Texturing: This process involves creating a pattern of raised studs or columns on the membrane surface during manufacturing. This method produces a well-defined, high-friction interface.

- Spray-On Roughening (Spray Texturing): This technique involves creating a roughened surface by spraying during production. This method can produce a different surface roughness profile compared to the stud technique.

Key Advantages: Unmatched Performance

1. Superior Slope Stability

The primary benefit of textured geomembranes is their significantly enhanced friction coefficient. With values that can be as high as 0.8 or more, they prevent slippage and instability on steep slopes, which is a critical consideration in landfill cell walls, dam cores, and other earthworks projects.

2. Exceptional Physical and Chemical Durability

Like their smooth counterparts, textured HDPE geomembranes offer outstanding durability. They possess high tensile strength (e.g., ≥28 MPa) and elongation at break (≥700%), allowing them to withstand significant stress and ground movement without failing.

3. Long-Term Service Life and Environmental Resistance

Formulated with carbon black and anti-aging additives, these geomembranes are built to last. They are designed to resist UV radiation, oxidation, and biological degradation, maintaining their performance for decades with a typical design life exceeding 30 years.

4. High Impermeability

Textured geomembranes provide an excellent barrier with an extremely low hydraulic conductivity, typically on the order of 1*10⁻¹³ cm/s, effectively preventing the migration of liquids or gases.

Comparison of Texturing Processes: Stud vs. Spray-On

| Feature |

Stud/Columnar Point Texturing |

Spray-On Roughening |

| Primary Characteristic |

Creates a pattern of raised studs or columns on the membrane surface |

Creates a roughened surface by spraying during production |

| Typical Friction Coefficient |

Can achieve higher friction coefficients (e.g., 0.8) due to distinct stud geometry |

Friction coefficient may vary based on the specific spray process and parameters |

| Manufacturing Process |

Often associated with processes like roll embossing or modified extrusion to form the studs |

Involves techniques where material is applied to create surface roughness |

| General Application Note |

Often preferred for applications requiring very high interface shear strength with soils or geosynthetics on steep slopes |

Provides a roughened surface suitable for many slope applications where enhanced friction is needed |

Applications: Ideal for Critical Projects

Textured geomembranes are specified for projects demanding the highest level of stability and reliability:

- Landfill Liners and Caps: Used in base liners and especially on side slopes to prevent waste slippage and ensure system integrity

- Water and Hydraulic Structures: Ideal for canal linings, reservoir dams, and pond liners where slope stability is crucial

- Mining and Industrial Containment: Used in heap leach pads, tailings dams, and process water ponds to contain materials safely on sloped terrain

- Transportation Infrastructure: Applied in road and railway embankments for reinforcement and separation

Installation Guidelines

Proper installation is key to performance. Key steps include:

- Subgrade Preparation: The foundation must be smooth, compacted, and free of sharp objects that could puncture the membrane

- Panel Deployment: Unroll the geomembrane panels, ensuring the textured side faces the soil or interface material

- Seaming: Panels are typically joined using dual-track thermal fusion welding, ensuring a seam strength equal to or greater than the parent material

- Protection Layer: A protective layer, such as a non-woven geotextile, is often placed over the geomembrane before backfilling

Why Choose Our Textured Geomembrane?

- Proven Performance: Our products meet or exceed international standards (e.g., GRI GM13, ASTM)

- Technical Expertise: We offer expert support from design through installation

- Quality Assurance: Consistent quality ensured by advanced manufacturing controls

Contact Us for Technical Data Sheets and Project Consultation

Let our experts help you select the right textured geomembrane for your project's specific requirements. Request a quote or sample today.

Textured Geomembrane: The Secure Foundation for Your Most Demanding Containment Challenges.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!