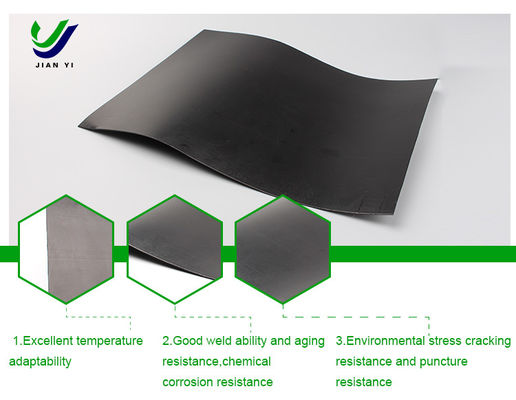

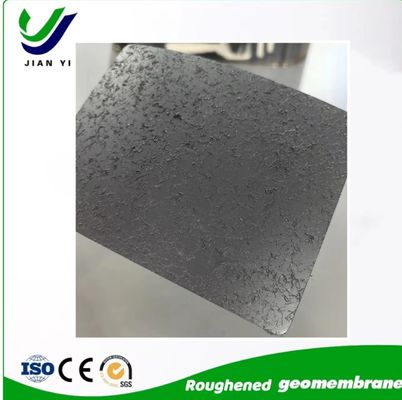

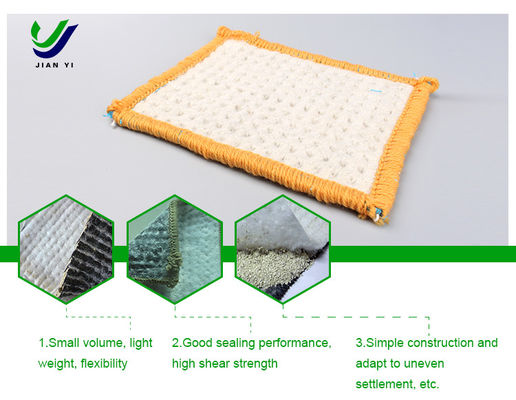

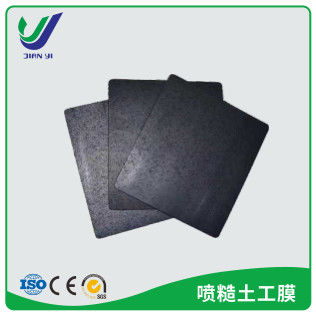

Textured Geomembrane is an engineered polyethylene membrane featuring a specially designed rough surface texture for enhanced friction and superior interface shear strength. Ideal for slope stabilization, landfill liners, and hydraulic applications, this product combines durability with exceptional anti-slip properties to ensure long-term project integrity.

Key Features

Dual-Surface Texture: Sandpaper-like finish on one or both sides for maximum friction resistance.

Material Excellence: Manufactured from premium-grade HDPE/LLDPE resin with UV stabilization and chemical resistance.

Shear Strength Optimization: Reduces interface slippage in steep slopes and high-stress environments.

Customizable Thickness: Available in 0.75mm to 3.0mm thicknesses to meet project-specific requirements.

Environmental Resilience: Resists punctures, tears, and biological degradation, suitable for harsh conditions.

Applications

1.Landfill liners & caps

2.Mining heap leach pads

3.Reservoir & canal linings

4.Road and railway embankments

5.Wastewater treatment ponds

Technical specification

(GB/T 17643-2011(GH-2T1,GH-2T2))

| Serial Number |

Project |

Index |

| Thickness(mm) |

0.75 |

1.00 |

1.25 |

1.50 |

2.00 |

2.50 |

3.00 |

| 1 |

Density (g/c㎡,≥) |

≥0.940 |

| 2 |

Textured Highth (mm) |

≥0.25 |

| 3 |

Yield Strength (N/mm,LD/TD) |

≥11 |

≥15 |

≥18 |

≥22 |

≥29 |

≥37 |

≥44 |

| 4 |

Breaking Strength (N/mm,LD/TD) |

≥8 |

≥10 |

≥13 |

≥16 |

≥21 |

≥26 |

≥32 |

| 5 |

Yeild Elongation Rate (%) |

≥12 |

| 6 |

Breaking Elongation Rate (%) |

≥100 |

| 7 |

Rectangular Tear Strength (N) |

≥93 |

≥125 |

≥160 |

≥190 |

≥250 |

≥315 |

≥375 |

| 8 |

Puncture Strength (N) |

≥200 |

≥270 |

≥335 |

≥400 |

≥535 |

≥670 |

≥800 |

| 9 |

Tensile Load Stress Cracking (Notch Constant Load Tensle Method) h |

≥300 |

| 10 |

Carbon Black Content(Rang) (%) |

2.0~3.0 |

| 11 |

Carbon Black Dispersion |

There is not more than one grade 3 in 10 data, and grade 4 and grade 5 are not allowed |

| 12 |

Oxidative Induction Time (OIT) |

Standard OIT (min)≥100 |

| High Pressure OIT (min)≥400 |

| 13 |

85℃ thermal aging (Atmospheric Pressure OIT Retention After 90 Day) |

≥55 |

| 14 |

Ultraviolet Irradiation After 1600 Hours, The OIT Retention(%) |

≥50 |

|

(CJ-T234-2006)

| Specification |

1.00mm |

1.25mm |

1.50mm |

2.00mm |

2.50mm |

3.00mm |

Remark |

| Item |

| Thickness (mm) |

1.00mm |

1.25mm |

1.50mm |

2.00mm |

2.50mm |

3.00mm |

|

| Textured Highth (mm) |

0.25 |

|

| Density (g/c㎡,≥) |

0.94 |

|

| Tensile Properties |

| Yield Strength (N/mm,LD/TD) |

15 |

18 |

22 |

29 |

37 |

44 |

|

| Breaking Strength (N/mm,LD/TD) |

10 |

13 |

16 |

21 |

26 |

32 |

|

| Yeild Elongation Rate (%) |

12 |

|

| Breaking Elongation Rate (%) |

100 |

|

| Rectangular Tear Strength (N) |

125 |

156 |

187 |

249 |

311 |

374 |

|

| Puncture Strength (N) |

267 |

333 |

400 |

534 |

667 |

800 |

|

Environmental Stress Crack Resistance (h)

(A single point of incision constant tensile method) |

300 |

|

| Carbon Black |

| Carbon Black Content(Rang) (%) |

2.0~3.0 |

|

| Carbon Black Dispersion |

Nine of 10 observation area should be grade 1 or grade 2, not more than 1 of grade3 |

|

| Oxidative Induction Time (OIT) |

| Standard OIT (min) |

100 |

|

| High Pressure OIT (min) |

400 |

|

| 85℃ Oven Ageing (Minimum Average) |

| 90 days after baking, the standard OIT retention(%) |

55 |

|

| 90 days after baking, the hight pressure OIT retention(%) |

80 |

|

| The Anti-UV Strength |

| Ultraviolet irradiation after 1600 hours, the standard OIT retention(%) |

50 |

|

| Ultraviolet irradiation after 1600 hours, the high pressure OIT retention(%) |

50 |

|

| -70℃ The Low Temperature Embrittlement Performance mpact |

Pass |

|

| Water Vapor Penetration Coefficient g.cm (cm2.s.Pa) |

≤1.0X10-13 |

|

| Dimensional Stability |

±2 |

|

Why Choose Our Textured Geomembrane?

Advanced Co-Extrusion Technology: Ensures uniform texture depth (0.3–0.8mm) without compromising tensile strength.

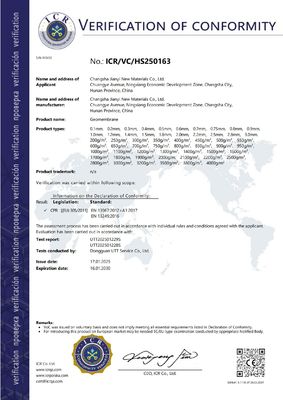

Third-Party Certified: Compliant with CE and ISO 9001 standards.

UV Resistance: Contains 2–3% carbon black for 20+ years of outdoor service life.

Seam Compatibility: Perfectly compatible with hot wedge welding techniques.

Installation Advantages

*Reduces need for additional anti-slip layers

*Maintains stability on slopes up to 45°

*Simplifies anchorage trench design

Packaging & Shipping

*Standard roll width: 3m–8m (customizable)

*Roll length: 50m–150m (depending on thickness)

*Protected with non-woven geotextile wrap

*Container-friendly packaging

Quality Assurance

*All textured geomembranes undergo rigorous QC testing including:

*Peel adhesion tests (texture bond strength ≥25 N/cm)

*Differential Scanning Calorimetry (DSC) for oxidative induction time

*Shear box testing for interface friction angles

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!