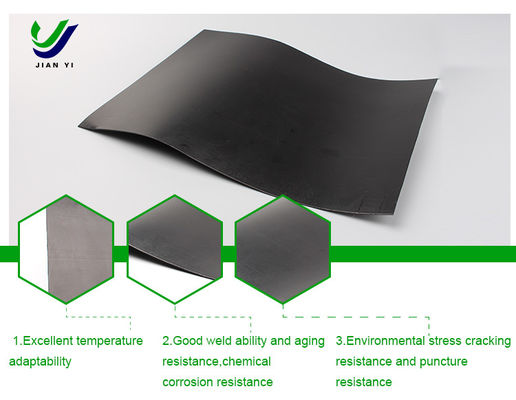

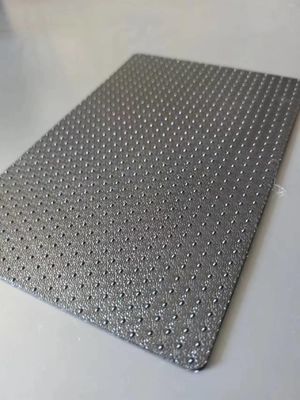

Advanced Production Process of HDPE Textured Geomembrane for Environmental Engineering

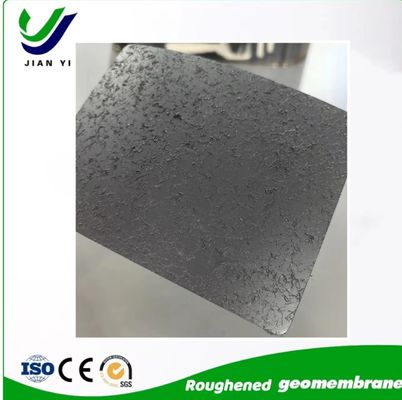

Definition and production process of roughened geomembrane

Roughened geomembrane is a product improved on the basis of the traditional production process of polyethylene anti-seepage membrane. Through specific production equipment and technology, the surface of the produced polyethylene anti-seepage membrane forms a granular rough surface. This rough surface is formed by letting the molten material flow out of the extrusion cavity, and then using the wind trough and hot air compression trough to introduce hot air into the wind cavity through the air inlet hole. The hot air is blown out through the hot air compression trough, blowing the material flowing out of the extrusion cavity into flocs, and finally these flocs fall on the surface of the geomembrane, thereby increasing the surface roughness and increasing the friction coefficient

Application scenarios of roughened geomembrane

Roughened geomembrane is widely used in many fields due to its unique surface roughness and excellent physical properties:

Environmental engineering

Landfill: used to prevent pollution of landfill leachate.

Tailings storage field: enhance the stability of tailings dams and prevent tailings loss.

Channel anti-seepage: effectively prevent water loss and soil erosion in agricultural irrigation and urban water supply systems.

Dam anti-seepage: Improve the safety of dams and prevent floods.

Subway projects: During subway construction, it is used to prevent groundwater infiltration and ensure construction safety

Construction projects

Highways, airports, and railways: Used for waterproof isolation of roads to increase road service life.

Tunnels: In subways, undersea tunnels and other projects, it prevents groundwater infiltration and ensures construction and operation safety

Performance characteristics of roughened geomembranes

Roughened geomembranes not only have all the advantages of ordinary geomembranes, but also have the following characteristics due to the increase in surface roughness:

Increase friction coefficient: Enhance adhesion with the base surface to prevent landslides.

Enhance tensile strength: Compared with smooth membranes, roughened membranes have stronger tensile strength.

Enhance resistance to load-bearing deformation: The rough particles on the surface of the rough membrane will form a small gap between the membrane and the base surface during laying, thereby enhancing the membrane's resistance to load-bearing deformation

Product Specification

* Thickness(mm): 0.30mm~3.00mm

* Width: 4m~8m

* Roll length: 50m~100m (customized request accept)

PS: Customized request accept for all above.

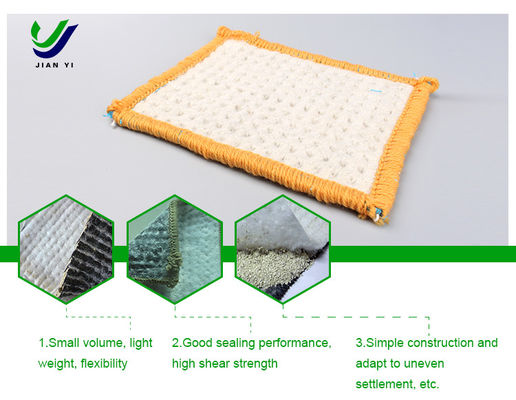

Geomembrane Series

Textured HDPE Geomembrane For Landfill (GB/T 17643-2011(GH-2T1,GH-2T2))

| Serial Number |

Project |

Index |

| Thickness(mm) |

0.75 |

1.00 |

1.25 |

1.50 |

2.00 |

2.50 |

3.00 |

| 1 |

Density (g/c㎡,≥) |

≥0.940 |

| 2 |

Textured Highth (mm) |

≥0.25 |

| 3 |

Yield Strength (N/mm,LD/TD) |

≥11 |

≥15 |

≥18 |

≥22 |

≥29 |

≥37 |

≥44 |

| 4 |

Breaking Strength (N/mm,LD/TD) |

≥8 |

≥10 |

≥13 |

≥16 |

≥21 |

≥26 |

≥32 |

| 5 |

Yeild Elongation Rate (%) |

≥12 |

| 6 |

Breaking Elongation Rate (%) |

≥100 |

| 7 |

Rectangular Tear Strength (N) |

≥93 |

≥125 |

≥160 |

≥190 |

≥250 |

≥315 |

≥375 |

| 8 |

Puncture Strength (N) |

≥200 |

≥270 |

≥335 |

≥400 |

≥535 |

≥670 |

≥800 |

| 9 |

Tensile Load Stress Cracking (Notch Constant Load Tensle Method) h |

≥300 |

| 10 |

Carbon Black Content(Rang) (%) |

2.0~3.0 |

| 11 |

Carbon Black Dispersion |

There is not more than one grade 3 in 10 data, and grade 4 and grade 5 are not allowed |

| 12 |

Oxidative Induction Time (OIT) |

Standard OIT (min)≥100 |

| High Pressure OIT (min)≥400 |

| 13 |

85℃ thermal aging (Atmospheric Pressure OIT Retention After 90 Day) |

≥55 |

| 14 |

Ultraviolet Irradiation After 1600 Hours, The OIT Retention(%) |

≥50 |

|

(CJ-T234-2006)

| Specification |

1.00mm |

1.25mm |

1.50mm |

2.00mm |

2.50mm |

3.00mm |

Remark |

| Item |

| Thickness (mm) |

1.00mm |

1.25mm |

1.50mm |

2.00mm |

2.50mm |

3.00mm |

|

| Textured Highth (mm) |

0.25 |

|

| Density (g/c㎡,≥) |

0.94 |

|

| Tensile Properties |

| Yield Strength (N/mm,LD/TD) |

15 |

18 |

22 |

29 |

37 |

44 |

|

| Breaking Strength (N/mm,LD/TD) |

10 |

13 |

16 |

21 |

26 |

32 |

|

| Yeild Elongation Rate (%) |

12 |

|

| Breaking Elongation Rate (%) |

100 |

|

| Rectangular Tear Strength (N) |

125 |

156 |

187 |

249 |

311 |

374 |

|

| Puncture Strength (N) |

267 |

333 |

400 |

534 |

667 |

800 |

|

Environmental Stress Crack Resistance (h)

(A single point of incision constant tensile method) |

300 |

|

| Carbon Black |

| Carbon Black Content(Rang) (%) |

2.0~3.0 |

|

| Carbon Black Dispersion |

Nine of 10 observation area should be grade 1 or grade 2, not more than 1 of grade3 |

|

| Oxidative Induction Time (OIT) |

| Standard OIT (min) |

100 |

|

| High Pressure OIT (min) |

400 |

|

| 85℃ Oven Ageing (Minimum Average) |

| 90 days after baking, the standard OIT retention(%) |

55 |

|

| 90 days after baking, the hight pressure OIT retention(%) |

80 |

|

| The Anti-UV Strength |

| Ultraviolet irradiation after 1600 hours, the standard OIT retention(%) |

50 |

|

| Ultraviolet irradiation after 1600 hours, the high pressure OIT retention(%) |

50 |

|

| -70℃ The Low Temperature Embrittlement Performance mpact |

Pass |

|

| Water Vapor Penetration Coefficient g.cm (cm2.s.Pa) |

≤1.0X10-13 |

|

| Dimensional Stability |

±2 |

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!