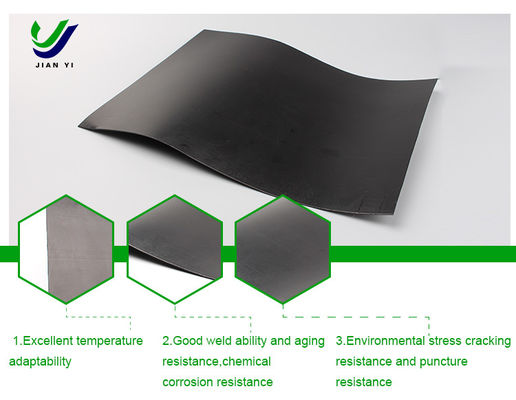

High-Strength HDPE Textured Geomembrane for Enhanced Stability and Performance

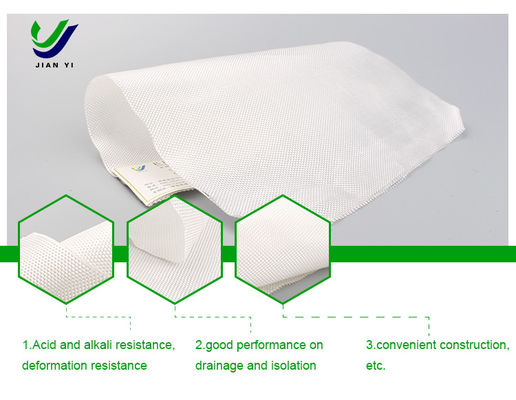

Overview of Sprayed Rough Geomembrane

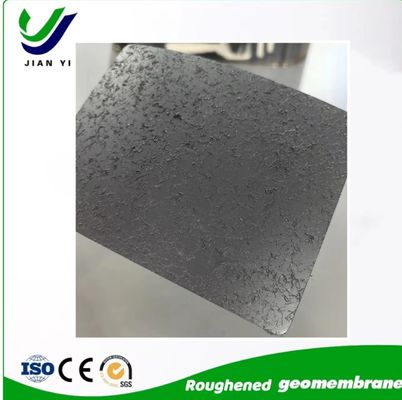

Sprayed Rough Geomembrane is a special geosynthetic material, mainly used for anti-seepage, anti-skid and enhancing the stability of engineering structures. It is based on the traditional production process of polyethylene anti-seepage membrane. By updating the production equipment, the surface of the polyethylene anti-seepage membrane produced forms a granular rough surface, thereby improving the friction performance of the geomembrane surface

Characteristics and Applications

Characteristics

Reliable anti-seepage effect: The permeability coefficient of the sprayed rough geomembrane is small, which can effectively prevent liquid penetration.

Easy to lay: Its design is convenient for construction personnel to lay.

High strength: It has high tensile strength, elongation at break and puncture resistance.

Stable material: It has strong resistance to chemical agents and can maintain stable performance in various harsh environments.

High joint strength: The joints are double-seam connected by a hot welding machine to ensure that the joints are not prone to leakage1.

Application

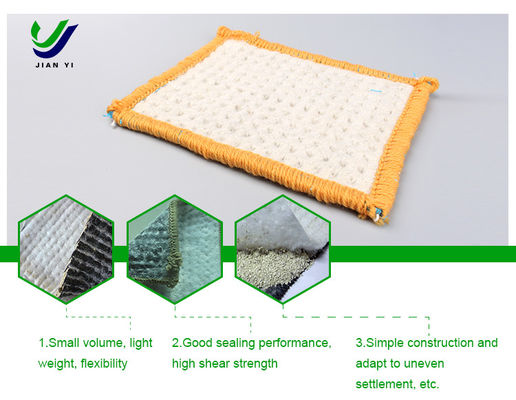

Sprayed Rough Geomembrane is widely used in engineering projects that require anti-seepage and enhanced friction, especially in projects where the surface of the slope membrane needs to be covered with soil and requires a large friction coefficient. For example, landfills, tailings storage sites, channel anti-seepage, dam anti-seepage and subway projects, etc.

Types

Sprayed rough geomembranes are available in two types: single rough surface and double rough surface. The specific choice depends on the project requirements. Both single rough surface geomembranes and double rough surface geomembranes are made of specially formulated virgin resins and produced by special processes. Among them, double rough surface geomembranes have more rough textures on their surfaces, so they perform better in increasing the friction coefficient and anti-slip function, and are more suitable for steep slopes and vertical anti-seepage projects

Manufacturing and materials

Sprayed rough geomembranes are usually made of high-density polyethylene (HDPE) or polypropylene as raw materials, and are refined through professional production equipment and special production processes. This material has excellent temperature adaptability, weldability, weather resistance and good aging resistance, making it an ideal choice for many high-demand projects

Conclusion

Sprayed rough geomembranes are a high-performance anti-seepage material. With its unique surface rough texture, it significantly improves the friction coefficient and anti-slip performance, and is widely used in various projects that require anti-seepage and enhanced friction. Whether it is single-surface or double-surface geomembrane, we can provide reliable solutions according to specific engineering needs.

Product Specification

* Thickness(mm): 0.30mm~3.00mm

* Width: 4m~8m

* Roll length: 50m~100m (customized request accept)

PS: Customized request accept for all above.

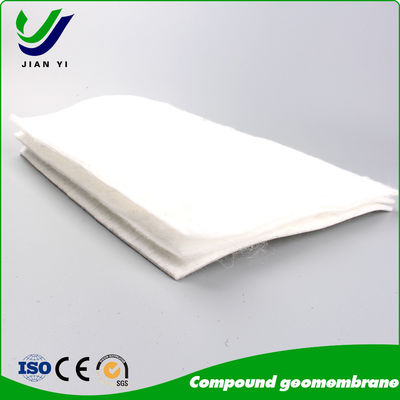

Geomembrane Series

Textured HDPE Geomembrane For Landfill (GB/T 17643-2011(GH-2T1,GH-2T2))

| Serial Number |

Project |

Index |

| Thickness(mm) |

0.75 |

1.00 |

1.25 |

1.50 |

2.00 |

2.50 |

3.00 |

| 1 |

Density (g/c㎡,≥) |

≥0.940 |

| 2 |

Textured Highth (mm) |

≥0.25 |

| 3 |

Yield Strength (N/mm,LD/TD) |

≥11 |

≥15 |

≥18 |

≥22 |

≥29 |

≥37 |

≥44 |

| 4 |

Breaking Strength (N/mm,LD/TD) |

≥8 |

≥10 |

≥13 |

≥16 |

≥21 |

≥26 |

≥32 |

| 5 |

Yeild Elongation Rate (%) |

≥12 |

| 6 |

Breaking Elongation Rate (%) |

≥100 |

| 7 |

Rectangular Tear Strength (N) |

≥93 |

≥125 |

≥160 |

≥190 |

≥250 |

≥315 |

≥375 |

| 8 |

Puncture Strength (N) |

≥200 |

≥270 |

≥335 |

≥400 |

≥535 |

≥670 |

≥800 |

| 9 |

Tensile Load Stress Cracking (Notch Constant Load Tensle Method) h |

≥300 |

| 10 |

Carbon Black Content(Rang) (%) |

2.0~3.0 |

| 11 |

Carbon Black Dispersion |

There is not more than one grade 3 in 10 data, and grade 4 and grade 5 are not allowed |

| 12 |

Oxidative Induction Time (OIT) |

Standard OIT (min)≥100 |

| High Pressure OIT (min)≥400 |

| 13 |

85℃ thermal aging (Atmospheric Pressure OIT Retention After 90 Day) |

≥55 |

| 14 |

Ultraviolet Irradiation After 1600 Hours, The OIT Retention(%) |

≥50 |

|

(CJ-T234-2006)

| Specification |

1.00mm |

1.25mm |

1.50mm |

2.00mm |

2.50mm |

3.00mm |

Remark |

| Item |

| Thickness (mm) |

1.00mm |

1.25mm |

1.50mm |

2.00mm |

2.50mm |

3.00mm |

|

| Textured Highth (mm) |

0.25 |

|

| Density (g/c㎡,≥) |

0.94 |

|

| Tensile Properties |

| Yield Strength (N/mm,LD/TD) |

15 |

18 |

22 |

29 |

37 |

44 |

|

| Breaking Strength (N/mm,LD/TD) |

10 |

13 |

16 |

21 |

26 |

32 |

|

| Yeild Elongation Rate (%) |

12 |

|

| Breaking Elongation Rate (%) |

100 |

|

| Rectangular Tear Strength (N) |

125 |

156 |

187 |

249 |

311 |

374 |

|

| Puncture Strength (N) |

267 |

333 |

400 |

534 |

667 |

800 |

|

Environmental Stress Crack Resistance (h)

(A single point of incision constant tensile method) |

300 |

|

| Carbon Black |

| Carbon Black Content(Rang) (%) |

2.0~3.0 |

|

| Carbon Black Dispersion |

Nine of 10 observation area should be grade 1 or grade 2, not more than 1 of grade3 |

|

| Oxidative Induction Time (OIT) |

| Standard OIT (min) |

100 |

|

| High Pressure OIT (min) |

400 |

|

| 85℃ Oven Ageing (Minimum Average) |

| 90 days after baking, the standard OIT retention(%) |

55 |

|

| 90 days after baking, the hight pressure OIT retention(%) |

80 |

|

| The Anti-UV Strength |

| Ultraviolet irradiation after 1600 hours, the standard OIT retention(%) |

50 |

|

| Ultraviolet irradiation after 1600 hours, the high pressure OIT retention(%) |

50 |

|

| -70℃ The Low Temperature Embrittlement Performance mpact |

Pass |

|

| Water Vapor Penetration Coefficient g.cm (cm2.s.Pa) |

≤1.0X10-13 |

|

| Dimensional Stability |

±2 |

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!