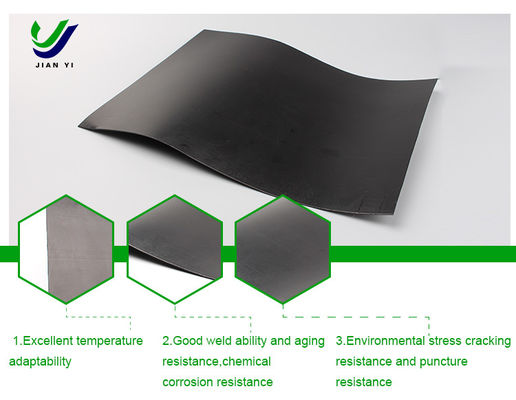

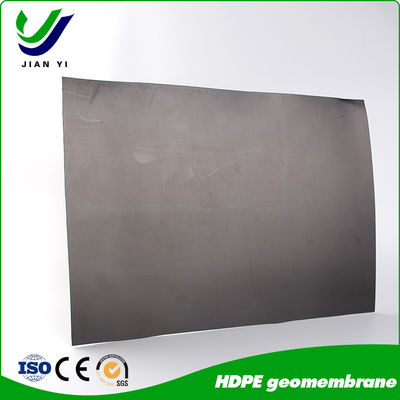

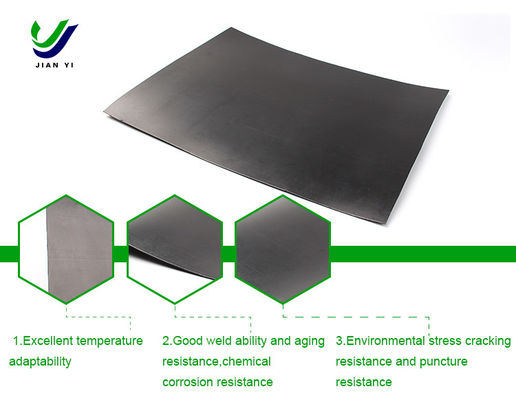

The waterproofing geomembrane liner is a kind of geosynthetic material, its raw material is the new polyethylene resin particles extracted from crude oil, which are processed by the special process of film calendering machine or film blowing equipment. The geomembrane manufacturer from China, Has its Geomembrane factory, which Can be customized, OEM is available, and CE certification.

HDPE Geomembrane Specifications:

|

Geomembrane Item

|

Value

|

|

Thickness/mm

|

0.75

|

1.0

|

1.25

|

1.5

|

2.0

|

2.5

|

3.0

|

|

Density,g/cm3

|

≥0.94

|

|

Tensile yield strength, N/mm

|

≥11

|

≥15

|

≥18

|

≥22

|

≥29

|

≥37

|

≥44

|

|

Tensile breaking strength, N/mm

|

≥20

|

≥27

|

≥33

|

≥40

|

≥53

|

≥67

|

≥80

|

|

Elongation at yield, %

|

≥12

|

|

Elongation at break,%

|

≥700

|

|

Tear Resistance, N

|

≥93

|

≥125

|

≥160

|

≥190

|

≥250

|

≥315

|

≥375

|

|

Puncture Resistance, N

|

≥240

|

≥320

|

≥400

|

≥480

|

≥640

|

≥800

|

≥960

|

Geomembrane Price:

The geomembrane price range is from $0.5/sqm- to $3/sqm, as the price is affected by the geomembrane material such as the HDPE geomembrane price is different from that of LLDPE geomembrane price, geomembrane thickness, geomembrane size, and geomembrane quantity.

Geomembrane Liner Cost:

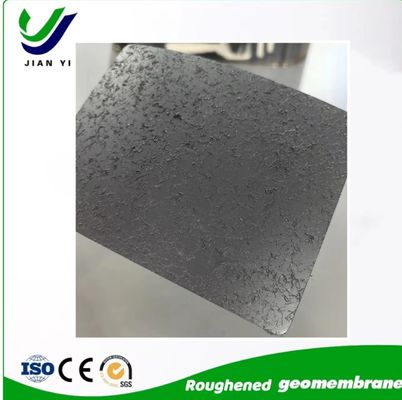

The cost of a smooth geomembrane liner can vary from $0.50 per square foot to $0.75 per square foot. Textured geomembrane liner will tend to cost $0.20 per square foot more than the smooth variety. Of course, this also depends on whether it is a geomembrane manufacturer or a geomembrane supplier. We are geomembrane manufacturers and geomembrane suppliers from China, worthy of your trust!

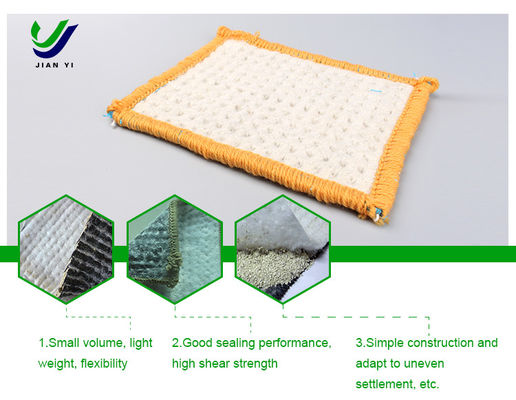

Geomembranes Functions and Applications:

What is geomembrane used for? Our customer HDPE liner projects include aquaculture (fish ponds, shrimp ponds), water conservancy (canals, dam), environmental protection (landfill sites, sewage treatment), mining (heap leaching ponds, tailings), agriculture (water reservoirs), and many other projects, customer satisfaction is 100%.

Geomembrane Agriculture Projects: water reservoirs, geomembrane dam liner, irrigation systems, canals.

Geomembrane Application: Geomembrane Mining

Geomembrane Mine Projects: heap leaching platforms, tailing.

Geomembrane Application: Geomembrane Oil & Gas

Geomembrane Oil & Gas projects: freshwater holding pond liner, flow back and production water pond liner, well pad liners, pit liners, secondary containment.

Geomembrane Installation Guide:

1. Do not drag or pull the geomembrane during transportation to avoid being stabbed by sharp objects.

2. Before cutting the geomembrane, the relevant dimensions should be measured, and then cut according to the actual situation.

3. When laying the geomembrane, a small number of welds should be sought. On the premise of ensuring quality, the raw materials should be saved as much as possible, and the quality should be guaranteed.

4. The lap width of the seam between the geomembrane and the geomembrane is generally not less than 10cm. Usually, the direction of the welding seam is parallel to the largest slope, that is, along the slope direction.

5. Usually in corners and deformed areas, the length of the seam should be shortened as much as possible. Except for special requirements, on slopes with a slope greater than 1:6, within 1.5 meters from the top slope or the stress concentration area, try not to set welds.

6. During the laying of the geomembrane, artificial folds should be avoided. When the temperature is low, it should be tightened as much as possible and flattened.

7. After the geomembrane is laid, walking on the membrane surface, moving tools, etc. should be minimized. Any objects that can cause harm to the impermeable membrane should not be placed on the membrane or carried on the membrane to avoid damage to the membrane. cause accidental damage.

If you need a more detailed geomembrane installation guide video, contact us to provide you with a geomembrane installation video and instruction manual for free!

Tip: Use the right power geomembrane welding machine correctly for geomembrane installation!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!