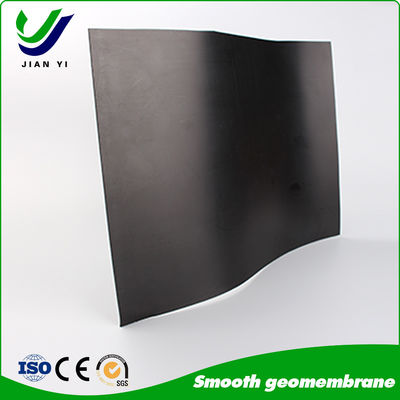

Smooth HDPE Geomembrane for Mine Tailings Pond Anti-Seepage

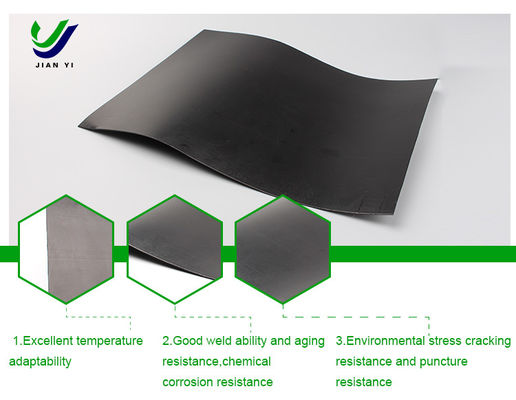

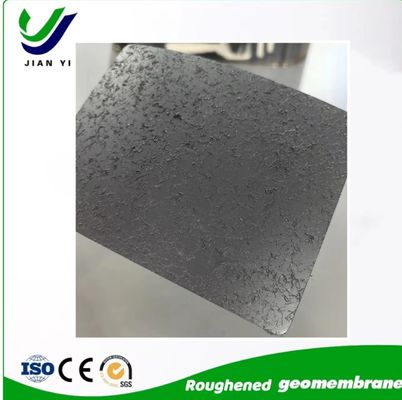

Our Smooth HDPE Geomembrane is a high-performance anti-seepage material specifically engineered for mine tailings ponds, leachate ponds, and water containment structures. Manufactured from 100% virgin HDPE resin using advanced extrusion molding technology, it features a smooth surface and uniform thickness for reliable performance.

Technical Specifications:

• Permeability coefficient: ≤1.0*10⁻¹³ cm/s

• Thickness range: 0.5mm to 3.0mm

• Width range: 2m to 8m (customizable)

• Tensile strength: ≥28MPa

• Elongation at break: ≥500%

Key Performance Features

Ultra-Low Permeability Anti-Seepage

Forms a complete impermeable barrier to prevent leakage of harmful substances including cyanide, sulfide, heavy metals, and leachate into soil and groundwater, effectively protecting the surrounding ecological environment.

Exceptional Chemical Corrosion Resistance

Withstands long-term exposure to acids, alkalis, salts, organic solvents, and other chemical substances commonly found in mining operations without aging, cracking, or degradation.

Superior Mechanical Properties

High tensile strength and elongation capabilities provide excellent resistance to puncture, tear, and deformation during installation and operational use.

Enhanced Weather Resistance

UV stabilizers protect against sunlight radiation and extreme temperature variations, ensuring long-term durability in harsh environmental conditions.

Application Scenarios

- Mine tailings ponds (core facility for storing mine tailings)

- Leachate collection ponds for treating leachate from tailings and waste rock

- Mine wastewater storage ponds

- Coal ash ponds in coal mines

- Chemical storage tanks in mining smelting workshops

- Groundwater protection barriers in mining areas

Installation Guidelines

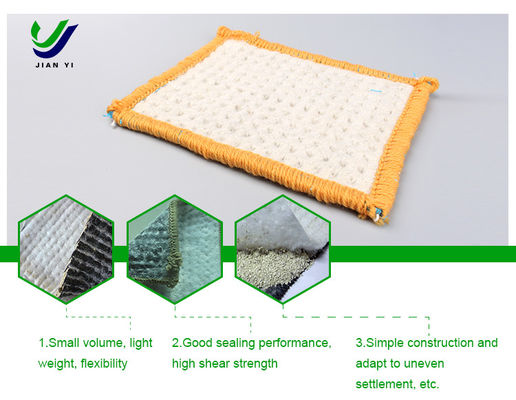

Surface Preparation: Base surface must be flat, clean, and free of sharp objects (stones, glass, steel bars). Fill pits and uneven areas with sand or fine soil.

Laying Procedure: Lay geomembrane without tension or wrinkles. Overlap adjacent membranes by 10-15cm (≤1.5mm thickness) or 15-20cm (>1.5mm thickness).

Welding Requirements: Use HDPE welding machine with welding strength ≥80% of base material. Conduct air pressure testing (pressure ≥0.2MPa, holding time ≥5 minutes) to verify seal integrity.

Storage & Maintenance: Protect from direct sunlight before installation using tarpaulin covers. Regularly inspect for damage and repair leaks or tears promptly with special welding rods.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!