Introduction: Engineered for Superior Performance and Long-Term Reliability

Discover the advanced capabilities of our PET (Polyethylene Terephthalate) fiber geotextiles, specifically engineered for demanding reinforcement and stabilization applications. Manufactured from high-tenacity continuous filament polyester yarns, these woven geotextiles offer exceptional tensile strength, minimal elongation, and outstanding resistance to environmental stressors. Ideal for permanent infrastructure projects, our PET geotextiles provide the critical support needed for soil reinforcement, load distribution, and long-term structural integrity in the most challenging conditions.

Key Advantages and Technical Superiority

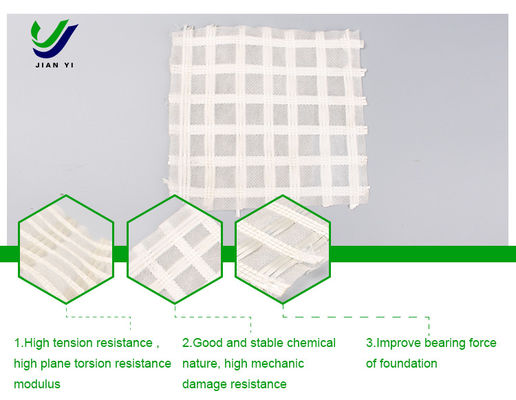

1. Exceptional Tensile Strength and Load-Bearing Capacity

PET geotextiles are characterized by their high tensile strength, making them uniquely suited for reinforcement applications. They effectively distribute loads over a wider area, reduce differential settlement, and enhance the overall bearing capacity of weak subsoils. This leads to more stable and durable construction outcomes.

2. Low Elongation and High Modulus

Unlike some geotextiles, PET fabrics exhibit low elongation under load (typically <12%). This high modulus property ensures minimal deformation under stress, providing predictable performance and maintaining structural stability in reinforced soil walls, steep slopes, and embankments.

3. Superior Resistance to Creep

Polyester fibers offer excellent resistance to creep—the tendency to deform slowly under persistent mechanical stress. This crucial characteristic ensures that the geotextile maintains its reinforcement function over the entire design life of the structure, often exceeding 100 years.

4. Excellent Durability and Environmental Resistance

PET geotextiles demonstrate:

-

Outstanding UV Resistance: Enhanced stabilization treatments protect against solar degradation during installation and service.

-

Hydrolytic Stability: Specifically formulated to resist degradation in various pH environments commonly encountered in soil.

-

Strong Biological and Chemical Resistance: Immune to rot, mildew, and most soil chemicals, ensuring consistent long-term performance.

5. Optimal Interaction with Soil

The precise weave pattern creates an ideal interface friction coefficient with various soil types. This allows for efficient stress transfer between the soil and the geotextile, maximizing reinforcement efficiency and slope stability.

Primary Applications and Project Solutions

-

Reinforced Soil Structures: Essential component in mechanically stabilized earth (MSE) walls, steepened slopes, and abutments.

-

Base Reinforcement for Pavements: Improves road performance on soft subgrades, reduces rutting, and extends pavement life for highways, railways, and access roads.

-

Embankment Stabilization: Provides tensile strength to ensure stability over soft foundations and prevents embankment failure.

-

Landfill and Erosion Control: Used in landfill cap reinforcement and as a robust underlayer for riprap in severe erosion control scenarios.

-

Foundation Support: Distributes loads for shallow foundations, reducing settlement under structures.

Material Properties and Specifications

-

Material: 100% Virgin High-Tenacity Continuous Filament Polyester (PET)

-

Structure: Woven (Plain Weave or Twill Weave for higher strengths)

-

Available Strengths: Wide range of tensile strengths from 20 kN/m to 400 kN/m to meet specific design requirements.

-

Roll Dimensions: Standard widths of 2m to 6m (6.5ft to 19.5ft), customized lengths available.

All our PET geotextiles are manufactured to comply with international standards such as ASTM, ISO, and GRI, ensuring consistent performance and quality assurance. Critical properties like tensile strength, tear resistance, and seam efficiency are rigorously tested and certified.

Why Choose Our PET Fiber Geotextile?

-

Proven Structural Performance: Backed by engineering data and successful project histories worldwide.

-

Long-Term Value: Reduced maintenance and longer service life provide a superior return on investment for critical infrastructure.

-

Technical Expertise: Our engineering support team assists with design methodology, specification, and installation protocols.

-

Quality Guaranteed: Every roll comes with a Certificate of Conformance, guaranteeing that the product meets all published specifications.

Selecting the Right Product for Your Project

The correct specification depends on soil parameters, design loads, and environmental conditions. Our technical team can guide you through the selection process based on:

Request Technical Information or a Quote

For detailed technical data sheets, sample requests, or project-specific quotations, contact our engineering team today. Let us provide you with the right reinforcement solution for your next challenging project.

Build Stronger. Build to Last.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!